Slurry Separators

Slurry Separators

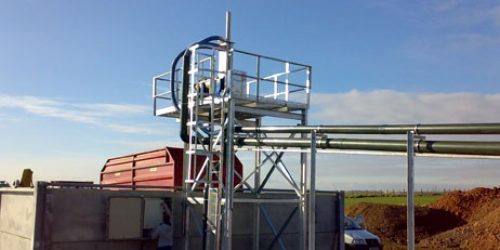

Unique Sepcom Horizontal & Vertical Screwpress Separators.

Re-using slurry offers enormous advantages in terms of transportation, storage, cleanliness and energy saving. Separating the solids in slurry from the liquid is the answer to the urgent problem of nitrates. Specially formulated, SEPCOM® is simple, reliable, efficient and economical.

The Sepcom separator is already used throughout the world as a slurry separator, it has many benefits over similar designed machines.

The unique Technopolymer screw is made up of easily replaceable sections, which reduces the running costs. This special screw rubs closer than the stainless steel screw, which keeps the screen clear and gives a better separation.

Another advantage of the Sepcom separator is the diaphragm outlet, this simple device allows a back-pressure to the separated material to increase separation and automatically adjusts to different slurries.

There are three models for the livestock sector with the Sepcom 15 at 15m3/hr, Sepcom 45 at 45m3/hr and the Sepcom 65 at 65m3/hr at 30% solids.

The sepcoms work on a low rate motor from 2.2kW up to 5.5kW.

Liquid Phase

- Easy to spread, mix, and pump

- Minimum residual sedimentation or incrustation

- Can be used for washing out sheds

- Excellent for ferti-irrigation

Solid Phase

- Shovelable, easy to store and convey

- Can be used as bedding for Animals

- Excellent as soil ammendant

- The odourless, non-percolating product can be marketed

- Compliance with recent norms and legislation on agronomic use of animal farming effluents in Europe and many other ecology aware countries will bring changes in farm management.

- Where the production of effluents is higher than the admissible load on the soil, this creates problems such as larger manure storage tanks requirements and larger areas for manure distribution with longer distances to cover. All this implies higher costs, and such problems will arise more and more frequently.

It is therefore useful to take a new management approach that favours the reduction of both transport and new distribution areas and addresses the fertilizing power of the farming effluent after separation.

Working with the Department of Rural Economic & Engineering of the University of Bologna, WAMGROUP® has analysed the problem of how to manage animal farming effluents in-depth, from both an economic and an environmental point of view, and evaluated the convenience of using a screw-type solids-liquid separator – an innovative aspect introduced by WAMGROUP® into product and process design, along with the manufacture machine components from engineering polymer SINT®.

First results in laboratory and field tests showed considerable advantages over competitors, mainly due to the polymer screw. The separating effect produces agronomic and management benefits. Looking at the two phases the following becomes evident:

- as less energy is required to distribute the separated liquid on fields, the problem of smearing over crops is greatly reduced;

- the separated liquid is more suitable for fertilization through irrigation with reduced addition of chemical fertilizers and lower costs;

- the distribution period is also extended, thus reducing storage volumes;

- the solid separated can be used in pre-ploughing and possibly destined to the fields most distant from the farm, generating lower costs and quicker delivery than common manure;

- the separated phase can be sold to other farmers or growers who require organic fertilizer;

- research results in some of the farms monitored have shown savings in effluent management ranging between €0.30 and 1.00 per cubic metre, in relation to the distance to cover and to the final destination of the separated solid.