Veneroni LT Range

Veneroni LT Range

The LT pump takes advantage of the driving power of the tractor and offers excellent performance even in heavy duty situations: presence of dense sewage with solid and fibrous bodies, transfers that are far from the pumping point, re-circulation beneath wide grids, etc.

The LT pump is equipped with a diverting valve with conical adjustable nozzle from which a high speed spout comes out, which homogenizes the sewage, eliminating all types of sedimentation.

The LT pump is supplied standard heat-galvanized; it is available also in the stainless steel version; the varnished trailer can be supplied heat-galvanised, on request.

The trailer allows positioning and subsequent recovery of the pump with only the help of the winch. No further interventions are required. A hydraulic winch version is also available.

Controls for rotation and operation of mixing spout; hydraulic actuators on request.

“M” version with a mixing impeller driven by the main transmission shaft.

Pumps LPM and LEM

The need to carry out mixing and pumping at the same time in the animal sewage treatment has pushed us to combine the efficiency of the LP and LE triturating pumps with the effectiveness of M blenders.

The result is a complete machine, which guarantees sewage pumping in modest volume tanks and maintains the homogeneous consistence, by taking advantage of the power of one electric motor. As a consequence the separators are remarkably better supplied, the operation of the frequent tanks emptying and of the use of sewage treatment automated systems is easier.

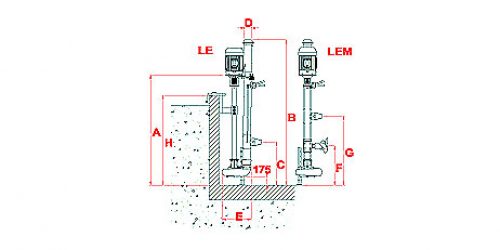

Dimensions: LT – M

| Model | D mm | A mm | B mm | C mm | E mm | F mm | H mm | |

|---|---|---|---|---|---|---|---|---|

| 12/540/ | 2 | 2360 | 2600 | 860 | 1.3 – 1.8 | |||

| 2.5 | 2860 | 3100 | 860 | 1.8 – 2.3 | ||||

| 3 | 3360 | 3600 | 1010 | 2.3 – 2.8 | ||||

| 3.5 | 120 | 3860 | 4100 | 1160 | 510 | 770 | 2.8 – 3.3 | |

| 4 | 4360 | 4600 | 1310 | 3.3 – 3.8 | ||||

| 4.5 | 4860 | 5100 | 1460 | 3.8 – 4.3 | ||||

| 5 | 5360 | 5600 | 1610 | 4.3 – 4.8 | ||||

| 15/540/ 15/1000/ | 2 | 2310 | 2550 | 870 | 1.3 – 1.8 | |||

| 2.5 | 2810 | 3050 | 870 | 1.8 – 2.3 | ||||

| 3 | 3310 | 3550 | 1020 | 2.3 – 2.8 | ||||

| 3.5 | 150 | 3810 | 4050 | 1170 | 580 | 790 | 2.8 – 3.3 | |

| 4 | 4310 | 4550 | 1320 | 3.3 – 3.8 | ||||

| 4.5 | 4810 | 5050 | 1470 | 3.8 – 4.3 | ||||

| 5 | 5310 | 5550 | 1620 | 4.3 – 4.8 | ||||

| 20/1000/ | 2 | 2310 | 2585 | 870 | 1.3 – 1.8 | |||

| 2.5 | 2810 | 3085 | 870 | 1.8 – 2.3 | ||||

| 3 | 3310 | 3585 | 1020 | 2.3 – 2.8 | ||||

| 3.5 | 200 | 3810 | 4085 | 1170 | 630 | 810 | 2.8 – 3.3 | |

| 4 | 4310 | 4585 | 1320 | 3.3 – 3.8 | ||||

| 4.5 | 4810 | 5085 | 1470 | 3.8 – 4.3 | ||||

| 5 | 5310 | 5585 | 1620 | 4.3 – 4.8 |

Dimensions: LT – M

| Model | rpm MAX | Rate of flow | Rated power of motor (kW) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P.T.O. | Pump | Q (l/s) | 25 | 40 | 55 | 70 | 85 | 100 | 115 | 130 | 145 | 160 | 175 | 190 | ||

| Q (l/min) | 1500 | 2400 | 3300 | 4200 | 5100 | 6000 | 6900 | 7800 | 8700 | 9600 | 10500 | 11400 | ||||

| Q (mc/h) | 90 | 144 | 198 | 252 | 306 | 360 | 414 | 468 | 522 | 576 | 630 | 684 | ||||

| LT 12/540 | 540 | 1600 | P (kW) | 14.5 | 14.8 | 15.2 | 16 | 17.5 | 19.5 | 40 | ||||||

| H (m) | 23 | 21 | 19 | 16 | 13 | 9 | ||||||||||

| LT 15/540 | 540 | 1600 | P (kW) | 28 | 29 | 29 | 30 | 30 | 32 | 34 | 37 | 40 | 60 | |||

| H (m) | 31 | 29 | 27 | 25 | 23 | 20 | 17 | 14 | 11 | |||||||

| LT 15/1000 | 900 | 1800 | P (kW) | 40 | 41 | 42 | 42 | 43 | 45 | 48 | 52 | 56 | 80 | |||

| H (m) | 37 | 35 | 33 | 30 | 27 | 24 | 21 | 17 | 13 | |||||||

| LT 20/1000 | 1000 | 2000 | P (kW) | 54 | 55 | 56 | 57 | 58 | 61 | 64 | 67 | 71 | 75 | 100 | ||

| H (m) | 43 | 41 | 38 | 35 | 32 | 29 | 25 | 21 | 17 | 13 | ||||||